800.460.5200

-

WELCOME TO GAUMER

Gaumer Process is an innovative and leading designer

and manufacturer of electric process heaters and

engineered systems for Power Generation, Oil & Gas,

Refinery, Petrochemical, Pulp & Paper, Marine and

Mining industry. -

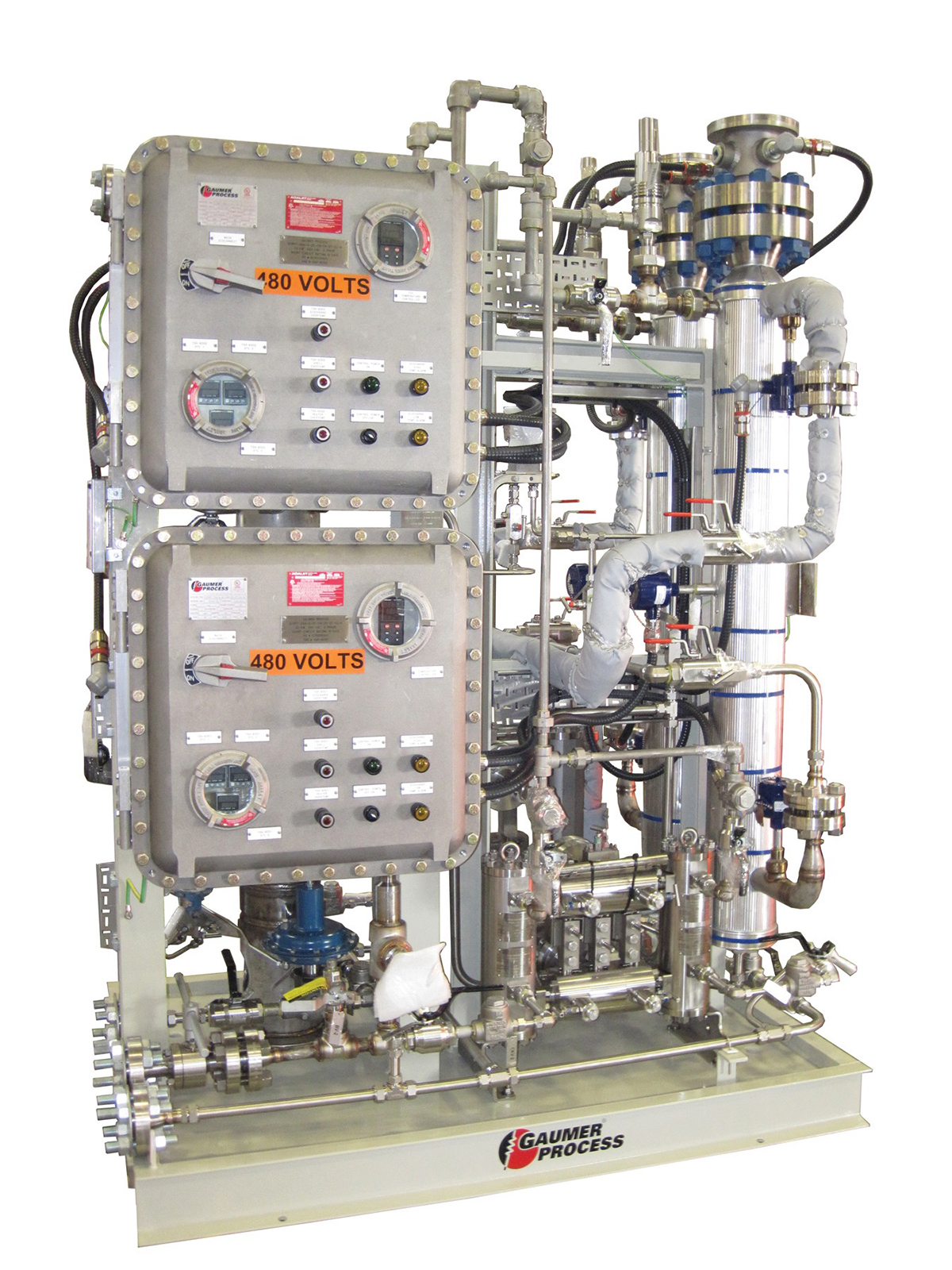

ELECTRIC HEATERS & CONTROLS

Low voltage (up to 600 V) & Medium Voltage (4160 V)

Gaumer Process has the experience and expertise to

provide certified electric process heaters and control

panels to domestic and international market. Serving

Global industry since 1962. -

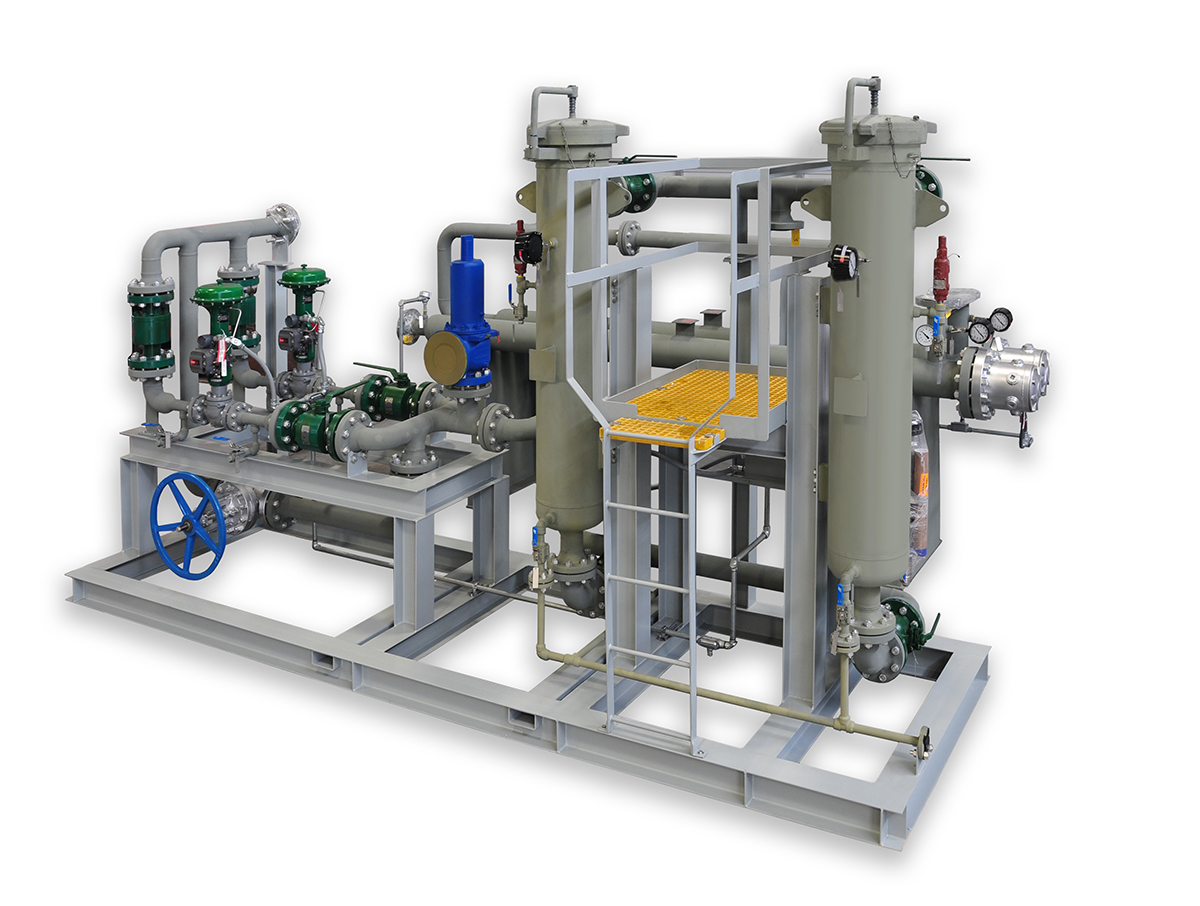

FUEL GAS CONDITIONING

Gaumer Process provides standard or custom

engineered fuel gas conditioning systems to meet the

most stringent fuel gas quality requirements of gas

turbines, engines and compressors. -

EXPEDITED DESIGN & MANUFACTURING

Large inventory of heater elements, experienced

engineering, procurement & project management team,

dedicated field service, start-up/commissioning

assistance and 24/7 emergency support, ensures that

the most aggressive delivery schedules are met with

confidence.

PHOTO GALLERY

LEARN MORE

- Lunch & Learn

- Request a Quote

- Product Brochure Pdf, 7.7 MB, opens in new window.

- Immersion Heater Catalog Pdf, 510.4 kB, opens in new window.

- 300 Lb Immersion Heater Catalog Pdf, 511 kB, opens in new window.

- 600 Lb Immersion Heater Catalog Pdf, 510.9 kB, opens in new window.

- Screw Plug Heater Catalog Opens in new window.

- SCRP Control Panel Catalog Opens in new window.

- Technical Info

GAUMER PROCESS · 13616 HEMPSTEAD ROAD · HOUSTON, TX 77040 · TEL: +1 (800) 460-5200 · [email protected]

© 2018 Gaumer Process All rights reserved.