800.460.5200

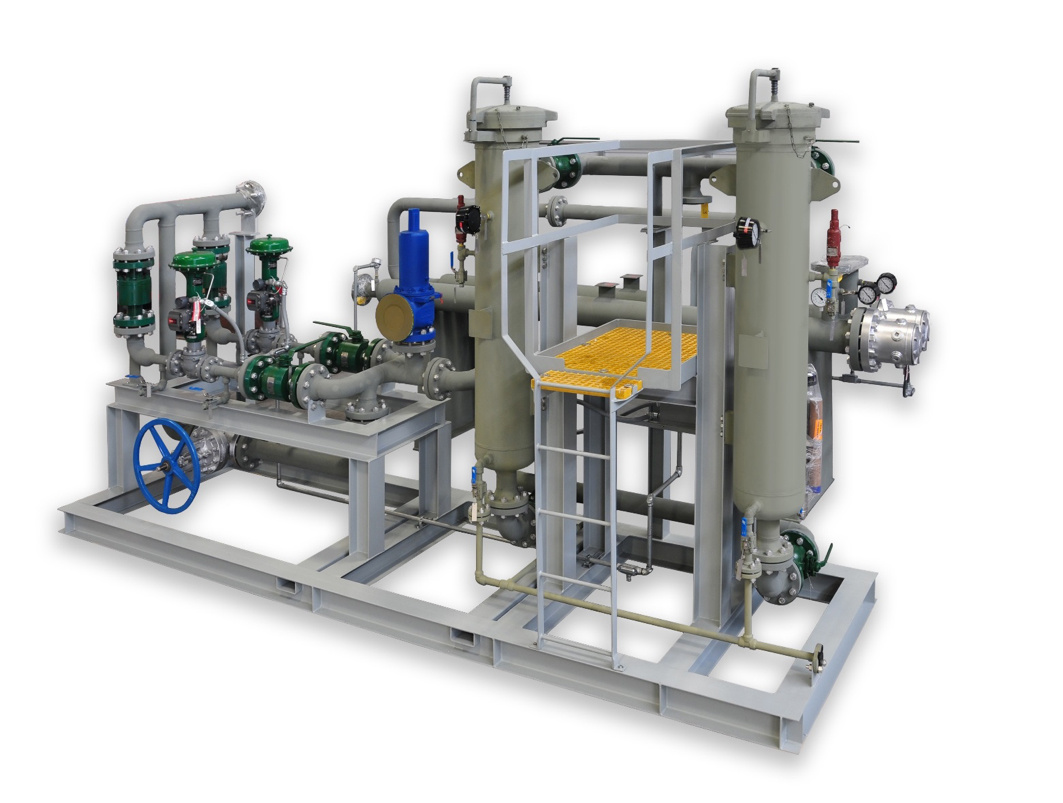

GAS FILTER COALESCER

Gaumer Process provides standard fuel gas filter coalescers (in accordance with Gaumer standard specifications) and custom engineered (in accordance with customer specifications), to meet the desired requirements of gas turbines, engines, burners and compressors of different makes.

Gas cleanliness requirements from gas turbine manufacturers dictates the gas to be clean, dry and free of liquids. Coalescer Filters are used to remove the solid and liquid particles from the gas stream. Pipeline quality gas is not clean enough for the gas turbines and thus the need for filter coalescers.

Coalescing, by definition, means “to come together”. It is a continuous process by which small aerosols come in contact with the fibers in filter media, uniting with other collected aerosols & growing to emerge as a droplet in downstream surface of media which is capable of being gravitationally drained.

Features

Efficiency of 99.9% - 0.3 microns or larger | PLC control system (optional) |

Skid mounted, trailer mounted or standalone | Ladder and platform per OSHA requirements (optional) |

Simplex or duplex arrangement | Quick availability based on pre-engineered design or custom engineered per equipment specifications |

ASME coded pressure vessel with relief valves | Complete process and mechanical guarantees |

Blind flange or quick opening enclosure for easy access of filter elements | Training and start-up/site commissioning assistance |

Manual or automatic liquid drains | Global certifications available such as PED, IECEx, ATEX, NR-13, etc. |

Level indication – local and remote |

Applications

Power Generation - Traditional power plant or mobile power generation unit |

Upstream, midstream and downstream |

Petrochemical |

PRODUCTS

INDUSTRIES

GAUMER PROCESS · 13616 HEMPSTEAD ROAD · HOUSTON, TX 77040 · TEL: +1 (800) 460-5200 · [email protected]

© 2018 Gaumer Process All rights reserved.