800.460.5200

Electric Fuel Gas Startup Superheater

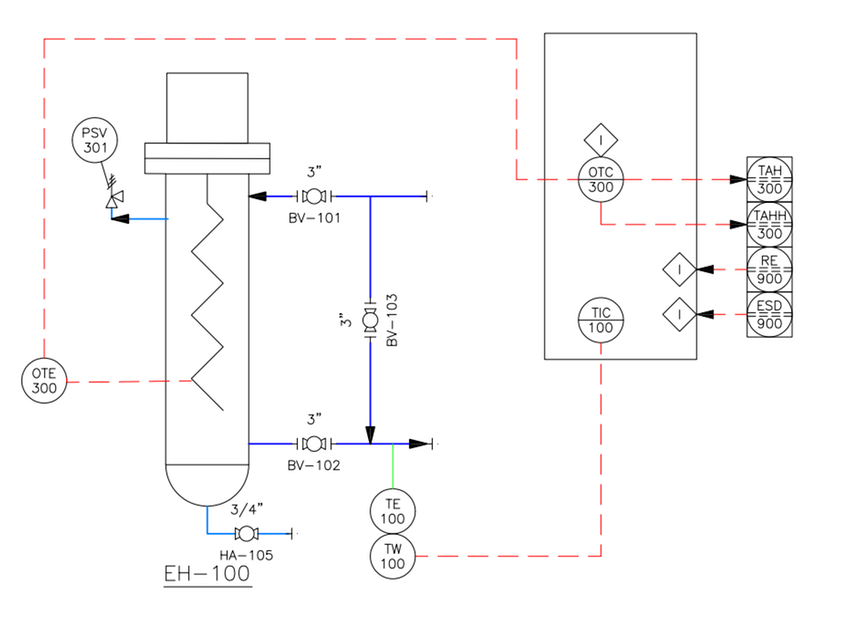

Electric Fuel Gas Startup Superheaters are used during initial startup of a Gas Turbine. During Startup the heater will raise the temperature of the fuel gas to the minimum required superheat level as defined by the turbine manufacturer. Startup Heaters, sometimes refered to as Black Start Heaters, superheat the gas until the performance heater can maintain the required temperature of the gas to the Turbine in a combined cycle power plant. The Startup/Superheater is placed after the final coalescing filter to prevent any moisture from dropping out prior to the Gas Turbine.

The Heater is typically controlled via 100% Silicon Controlled Rectifier (SCR) or Thyristor. It is common to power the heater with a generator during startup. If a generator is used for startup power, it is recommended that the SCR Controlled heater does not exceed 25% of the Generator Duty to prevent cycling of the Generator. A SCR/Step Control Scheme is employed to prevent the cycling of the Generator.

Standard Features

Skid Mounted System, Pre-Wired |

Heater and Vessel ASME Certified to ASME Section VIII Div 1 |

Hazardous Area Heater Certified to CSA, ATEX or IECEx |

Bypass line with Fire Safe Ball Valves |

Type Z Purged Control Panel for Class I Div 2, Class I Zone 2 or IEC Zone 2 |

Molded Case Circuit Breaker for incoming power and protection |

Class J or NH Type fast acting fuses for circuit protection |

Panel is Ul/cUL certified |

Nema 4 Carbon Steel Control Panel |

Thermal Relief PSV Included |

Alloy 800 Heating Elements for Superior Corosion and Heating |

Type K Thermocouple Attached to the Heater Element Sheath for overtemperature Protection |

Type K Thermocouple inside of 304SS Thermowell for process control |

Structural Steel Skid Base |

Digital PID Temperature Indicating Controller (TIC) for Process Control |

Digital Overtemperature Controller (OTC) for High Temprature shutdown |

Emergency Shutdown Signal from Customer Control System |

Status signals from Control Panel to Customer Control System |

Remote Setpoint from Customer Control System |

Process Temperature Re-Transmission to Customer Control Sytem |

Heater Running Status Singal to Customer Control System |

Heater Drain with Ball Valve |

Optional Features

Delta Temperature Control |

Trunnion Mounted Ball Valves |

Other Temperarture Sensors such as RTD or Type E Thermocouples |

Pressure Indicators |

Temperature Indicators |

Flow Transmitters |

Temperature Transmitters |

Pressure Transmitters |

Automated Valves |

Nema 4X Control Panel (304 or 316) |

300 lb rated system

300# Rated System | ||||||||

PN | kW | Amps | Htr Dia | Ele | Circuits | Line Size | Skid L (feet) | Skid W (feet) |

FGSH-48-3 | 48 | 57.7 | 6 | 12 | 2 | 2 | 6 | 4 |

FGSH-60-3 | 60 | 72.2 | 8 | 12 | 3 | 3 | 15 | 4.5 |

FGSH-90-3 | 90 | 108.3 | 8 | 18 | 3 | 3 | 6.5 | 4.5 |

FGSH-120-3 | 120 | 144.3 | 8 | 24 | 4 | 4 | 6.5 | 4.5 |

FGSH-150-3 | 150 | 180.4 | 10 | 30 | 5 | 4 | 7 | 5 |

FGSH-180-3 | 180 | 216.5 | 10 | 36 | 6 | 6 | 7.5 | 5 |

FGSH-216-3 | 216 | 259.8 | 10 | 36 | 6 | 6 | 7.5 | 5 |

FGSH-252-3 | 252 | 303.1 | 12 | 42 | 3 | 6 | 8 | 5.5 |

FGSH-288-3 | 288 | 346.4 | 12 | 48 | 4 | 6 | 8 | 5.5 |

FGSH-324-3 | 324 | 389.7 | 12 | 54 | 6 | 6 | 8 | 6.5 |

FGSH-360-3 | 360 | 433.0 | 14 | 60 | 5 | 8 | 8.5 | 6.5 |

FGSH-405-3 | 405 | 487.2 | 12 | 54 | 6 | 8 | 8.5 | 6.5 |

FGSH-450-3 | 450 | 541.3 | 14 | 60 | 10 | 8 | 8.5 | 7.5 |

FGSH-540-3 | 540 | 649.5 | 14 | 72 | 8 | 8 | 9 | 11.5 |

FGSH-630-3 | 630 | 757.8 | 16 | 84 | 14 | 10 | 9.5 | 11.5 |

600 lb rated system

600# Rated System | ||||||||

PN | kW | Amps | Htr Dia | Ele | Circ. | Line | Skid L | Skid W |

FGSH-48-6 | 48 | 57.7 | 6 | 12 | 2 | 2 | 6.5 | 4.5 |

FGSH-60-6 | 60 | 72.2 | 8 | 12 | 3 | 3 | 7 | 4.5 |

FGSH-90-6 | 90 | 108.3 | 8 | 18 | 3 | 3 | 7 | 4.5 |

FGSH-120-6 | 120 | 144.3 | 8 | 24 | 4 | 4 | 7.5 | 4.5 |

FGSH-150-6 | 150 | 180.4 | 10 | 30 | 5 | 4 | 8 | 5 |

FGSH-180-6 | 180 | 216.5 | 10 | 36 | 6 | 6 | 8 | 5 |

FGSH-216-6 | 216 | 259.8 | 10 | 36 | 6 | 6 | 8 | 5 |

FGSH-252-6 | 252 | 303.1 | 12 | 42 | 3 | 6 | 8.5 | 5.5 |

FGSH-288-6 | 288 | 346.4 | 12 | 48 | 4 | 6 | 8.5 | 5.5 |

FGSH-324-6 | 324 | 389.7 | 12 | 54 | 6 | 6 | 8.5 | 6.5 |

FGSH-360-6 | 360 | 433.0 | 14 | 60 | 5 | 8 | 9.5 | 6.5 |

FGSH-405-6 | 405 | 487.2 | 12 | 54 | 6 | 8 | 9 | 6.5 |

FGSH-450-6 | 450 | 541.3 | 14 | 60 | 10 | 8 | 9.5 | 7.5 |

FGSH-540-6 | 540 | 649.5 | 14 | 72 | 8 | 8 | 9.5 | 11.5 |

FGSH-630-6 | 630 | 757.8 | 16 | 84 | 14 | 10 | 10.5 | 11.5 |

PRODUCTS

INDUSTRIES

GAUMER PROCESS · 13616 HEMPSTEAD ROAD · HOUSTON, TX 77040 · TEL: +1 (800) 460-5200 · [email protected]

© 2018 Gaumer Process All rights reserved.